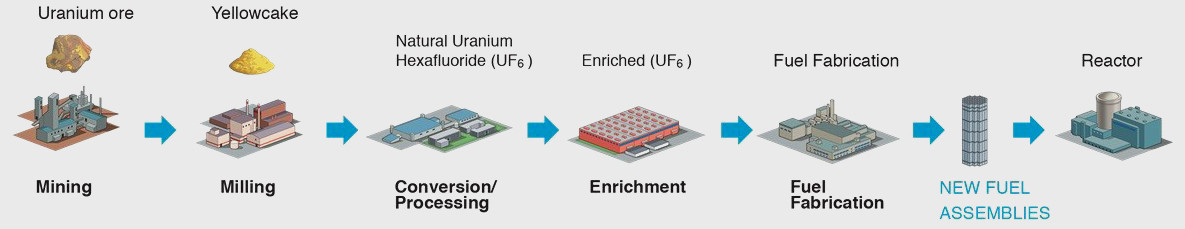

The Nuclear Fuel Cycle

In order for a nuclear energy plant to use uranium as fuel, the element must undergo a careful manufacturing process. To become the fuel used in nuclear reactors, uranium goes through five main steps.

1. Mining: Just like oil and coal, the raw material for nuclear fuel – uranium – comes from beneath the Earth’s surface. Rich deposits of uranium are found in mines in nearly 20 countries around the world. More than two-thirds of the world’s mined uranium comes from Kazakhstan, Canada and Australia. Uranium ore is extracted during the mining process and is taken to a mill.

2. Milling: At the mill, the uranium is separated from other substances and crushed to the size of gravel. Chemicals are then used to dissolve the uranium, turning it into a liquid solution. Once this solution dries, it forms a uranium oxide powder called ‘yellowcake’. Yellowcake itself cannot be used to generate electricity. The state of this material is similar to oil just removed from the Earth. Yellowcake is carefully packed into drums and sent to a conversion facility.

3. Conversion: Conversion facilities are operated by specialized companies with the technical know-how for the conversion process. Nearly all of the world’s uranium conversion takes place in Canada, China, France, Russia and the United States. The facilities operate under strict international regulations.

During conversion, scientists use chemical processes to convert yellowcake into a gas called uranium hexafluoride (UF6). This gas is loaded into special storage cylinders. When the gas cools to room temperature, it turns into a solid. The solidified UF6 is shipped to an enrichment facility.

4. Enrichment: Similar to conversion facilities, there is a limited number of countries who operate enrichment facilities. These include China, France, Germany, the Netherlands, Russia, the United Kingdom and the United States.

As part of its nuclear energy policy, the United Arab Emirates (UAE) made the decision to forgo domestic enrichment and reprocessing of nuclear fuel, two key elements of the country’s commitment to non-proliferation.

At an enrichment facility, the solidified UF6 is transformed back into a gas, and the uranium concentration is increased so that it is usable for nuclear fuel. It is then cooled and returned to storage cylinders. The enriched uranium is then shipped to a fuel fabrication plant.

5. Fabrication: More than a dozen countries are home to fuel fabrication facilities, including Korea. During the fabrication process, the UF6 gas is converted into a powder called uranium dioxide (UO2).

A machine forms the UO2 powder into small pellets that are about the size and shape of a pencil eraser. Then, a furnace heats the powder until it becomes solid and the pellets are hardened and shaped to very precise dimensions.

The pellets are loaded into metal tubes which are resistant to chemical corrosion, high temperatures, heavy weight, constant vibration, and fluid and mechanical impacts.

When bundled together, these tubes create a fuel assembly. One of the nuclear reactors in Barakah requires 241 fuel assemblies and each one can last up to six years in a reactor.

What are the three biggest myths in nuclear energy?

01

Radiation is man made

Radiation is energy in motion. There are many natural sources of radiation that we live with safely every day such as cosmic radiation from the sun.

02

Nuclear reactors can explode like bombs

It is not possible for a nuclear energy plant to explode like a bomb, these plants are designed to produce electricity safely and reliably.

03

It's not safe to be near a nuclear energy plant

If you stood at the site boundary for a whole year, you would receive less than a quarter of the radiation from a chest x-ray.